| Tenebrio molitor is a model of sustainability… but its impact loses strength if we keep packaging it in conventional plastics. This article explores the challenges and solutions of sustainable packaging for Tenebrio-based products, offering inspiring examples and a forward-looking perspective on the circular economy. |

Introduction

The world is desperately seeking alternative proteins. Tenebrio molitor is already farmed using less water, less land, and with very low emissions. Yet there is one detail that can overshadow this innovation: packaging.

Producing a sustainable food product is only half the story—if it’s delivered in a traditional plastic bag, the message loses credibility.

This is where sustainable packaging becomes a key factor: it not only protects the product but also becomes part of the story we tell the consumer.

The packaging challenge

Tenebrio products (protein flours, dehydrated snacks, oils) have very specific needs:

- Moisture protection: Tenebrio flour is hygroscopic and can lose its properties if not stored correctly.

- Antioxidant barrier: Tenebrio oils contain lipids that require well-sealed packaging to prevent rancidity.

- Extended shelf life: as an emerging market, products sometimes travel long distances before reaching consumers.

So far, conventional plastic has provided a practical solution. But if we want Tenebrio to be perceived as 100% green, we need packaging that lives up to that promise.

Innovations that inspire

The good news: there are already materials capable of replacing conventional plastic.

- Compostable packaging

Made from PLA, cornstarch, or plant fibers like sugarcane bagasse, these packages can decompose in composting facilities in just a few months. Beyond being functional, they convey a clear message to consumers: “this package returns to the earth.”

- Edible films

One of the most striking ideas: packaging that can be eaten along with the product. Made from algae, milk proteins, or chitosan (derived from the chitin found in Tenebrio), this innovation has a double impact: it surprises consumers and reinforces the circular economy.

- Recycled paper with natural coatings

Recycled paper combined with biodegradable barriers is ideal for lightweight, practical, and visually appealing packaging. It works especially well for small formats such as pouches or single-serve protein flour portions.

Lessons from other sectors

Insect farming doesn’t start from scratch; it can learn from industries already applying innovative packaging.

- Eco-snacks: brands using recycled paper bags with vegetable-based inks, emphasizing naturalness.

- Premium coffee: compostable capsules replacing aluminum and plastic, winning over consumers through ecological consistency.

- Sports supplements: returnable or refillable packaging that promotes responsible consumption and builds customer loyalty.

Adopting these strategies in this sector not only reduces waste but positions Tenebrio as a modern, innovative, and conscientious product.

Packaging = Communication

Packaging is not a minor detail; it is the consumer’s first contact with the product.

A well-designed package can be decisive for Tenebrio’s acceptance, especially in markets where it still generates curiosity—or hesitation.

Sustainable packaging communicates:

- Consistency: the product and its packaging send the same green message.

- Innovation: the brand appears pioneering, bold, and aligned with global trends.

- Trust: well-designed packaging conveys quality and professionalism, essential to attract first-time Tenebrio consumers.

On social media, where aesthetics matter, an attractive package can become a viral communication tool.

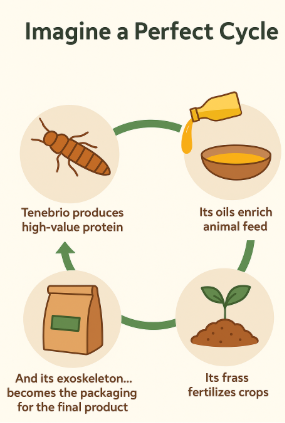

Full circular economy

The most promising future lies in Tenebrio’s own biology: its exoskeleton contains chitin, which can be transformed into chitosan to create biodegradable, antimicrobial packaging.

Imagine a perfect cycle:

- Its oils enrich animal feed.

A model where literally nothing goes to waste, and where the insect not only feeds but also wraps.

Final thoughts

Tenebrio molitor is much more than a protein source. It is a symbol of innovation and sustainability.

If we want it to conquer both the table and the minds of consumers, we must care for every detail.

Packaging is not an accessory; it is part of the experience.

Because the future isn’t wrapped in plastic—it’s wrapped in circular ideas that change the way we produce, consume, and communicate.

References

Nilsson, F., Silva, N., & Schelin, J. (2024). Single-use versus reusable packaging for perishable liquid foods – Exploring evidence from research on climate impact and food safety. Resources, Conservation and Recycling, 207. https://doi.org/10.1016/j.resconrec.2024.107655

Muñoz-Tebar, N., Pérez-Álvarez, J. A., Fernández-López, J., & Viuda-Martos, M. (2023). Chitosan edible films and coatings with added bioactive compounds: Antibacterial and antioxidant properties. Polymers (Basel) https://doi.org/10.3390/polym15020396

Matloob A, Ayub H, Mohsin M, Ambreen S, Khan FA, Oranab S, Rahim MA, Khalid W, Nayik GA, Ramniwas S, Ercisli S. A Review on Edible Coatings and Films: Advances, Composition, Production Methods, and Safety Concerns. ACS Omega. 2023 https://doi.org/10.1021/acsomega.3c03459

Larisa Ilijin, Maria Vesna Nikolić, Zorka Z. Vasiljević, Dajana Todorović, Marija Mrdaković, Milena Vlahović, Dragana Matić, Nenad B. Tadić, Vesna Perić-Mataruga, Sourcing chitin from exoskeleton of Tenebrio molitor fed with polystyrene or plastic kitchen wrap, International Journal of Biological Macromolecules, Volume 268, Part 2 https://pubmed.ncbi.nlm.nih.gov/38649081/

Mengyao Liu, Hualei Chen, Fei Pan, Xinning Wu, Yuan Zhang, Xiaoming Fang, Xiangxin Li, Wenli Tian, Wenjun Peng, Propolis ethanol extract functionalized chitosan/Tenebrio molitor larvae protein film for sustainable active food packaging, Carbohydrate Polymers, Volume 343, 2024 https://doi.org/10.1016/j.carbpol.2024.122445

https://www.vitafoodsinsights.com/sustainability/why-sustainable-packaging-for-supplements-matters