| When you start producing Tenebrio molitor at a certain scale, there comes a moment when you realize the real bottleneck isn’t the insect itself. It’s everything surrounding it: the space, the workflows, how you move through the facility, how much time you waste on repetitive tasks, and how difficult it is to scale without everything turning into a mess. |

This happened to us. We stopped thinking about “which crate to use” and started thinking about how we wanted the farm to function internally. That is exactly where equipment design began to play a central role.

Layout Changes Everything (When You Start Producing for Real)

When someone first thinks about setting up a Tenebrio molitor farm, it’s normal to focus on the biology: temperature, humidity, feeding, cycles… All of that is important, of course. But over time, you realize something key: a farm succeeds or fails based on its internal design.

The layout, workflows, equipment, ease of handling, and the ability to automate simple processes are what ultimately save you time, money, and headaches.

In our case, the shift happened when we stopped thinking about “breeding crates” and started thinking about a production system: How does the feed enter? How is it distributed? How are the trays handled? How are they stacked? How are they cleaned? How do they integrate into an automated work line?

Equipment That Supports the Work, Not Complicates It

One of the things we value most about the Beetle-Box system is that it’s designed for the day-to-day reality of a farm. These are breeding crates that are easy to handle, don’t get in the way, and make the job easier when you’ve spent hours moving trays.

Ergonomics matter here much more than it seems. When you can work more comfortably and faster with less effort, the entire system becomes more efficient. You notice this in both productivity and the morale of the team working on the farm.

Ready to Automate Without Losing Your Mind

Not every farm will be fully automated from day one. And that’s okay. The important thing is that your equipment isn’t a bottleneck when you’re ready to take the next step.

The Beetle-Box design allows for the integration of simple, realistic automations—the kind you can actually implement in a mid-sized farm. More agile feeding systems, organized repetitive movements, and clear input/output flows. Small changes that, together, make production much faster without requiring massive investments.

Ventilation, Cleaning, and Handling by Design

When equipment is well-planned, many common issues simply disappear. Ventilation is sufficient without complex setups, handling is straightforward, and cleaning doesn’t turn into an endless chore.

This doesn’t just save time; it brings stability to the production process. Less improvisation, fewer “band-aid” fixes, and more control over what happens inside the farm.

Optimizing Space: The Key to Farm Profitability

In mid-sized farms, space is often one of the biggest constraints. Expanding facilities isn’t always possible, so learning to make the most of what you already have is vital.

A well-designed, stackable system allows you to increase production without increasing square footage. Utilizing height, streamlining processes, and keeping everything accessible makes the farm run better without the need for construction or drastic changes.

Logistics: Something You Only Value When You Crunch the Numbers

Some decisions seem secondary until you start moving volume. A system that allows you to ship up to 9,900 or 10,000 units in a single truck represents a massive logistical saving.

Fewer shipments, lower costs, fewer storage issues, and a smaller environmental footprint. It’s one of those things you don’t notice at first, but it makes all the difference as the project grows.

Working with Beetles and Egg Laying

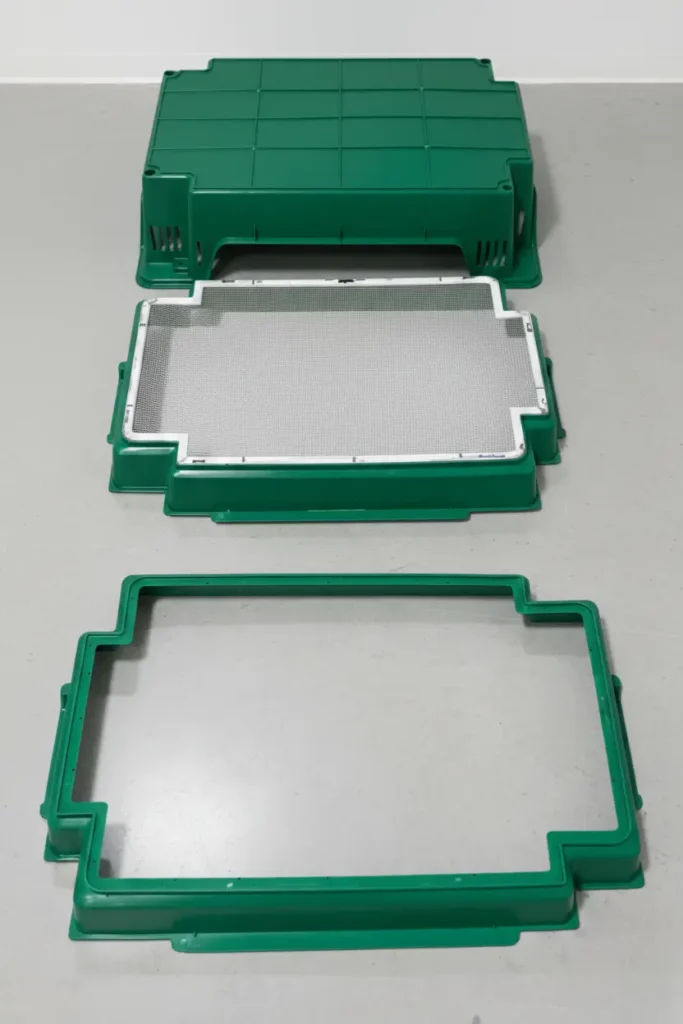

In the reproductive phase, the mesh screens play a key role and, honestly, they are a game changer in how the work is done.

The screens are designed to correctly separate the beetles from the eggs, preventing cannibalism and allowing for a much better utilization of each reproductive cycle.

In the end, what used to require constant handling and hours of manual labor becomes a much cleaner, more organized, and predictable process. For a farm that wants to scale without going crazy, these types of simple solutions are what actually make reproduction profitable.

Made in Spain and Food-Grade Certified

Working with equipment manufactured in Spain, with food-grade certification, provides something very important: trust. Knowing that the materials are suitable, comply with regulations, and have quality control behind them gives you peace of mind (especially in a sector that is becoming increasingly professionalized and regulated).

In the End, It’s All About Working Better

Over time, you learn that improving a farm doesn’t always mean producing more, but producing better. Thinking through the design, layout, workflows, and equipment is one of the most important decisions you can make from the start.

Beetle-Box isn’t just a crate. It’s part of a philosophy of understanding the farm as a well-thought-out system where everything fits and the work flows.

Want to learn more or purchase insect breeding equipment? Visit our website For Insect Farming