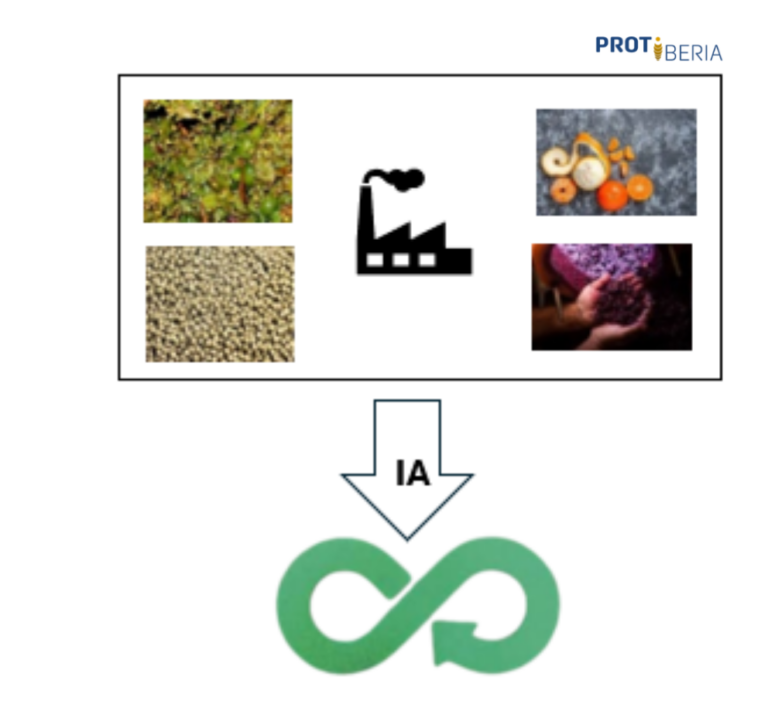

| By-products from the agri-food industry can be given a second life by being used as insect feed, thanks to their ability to efficiently convert nutrients. Using artificial intelligence as a tool, it is possible to optimise the selection and management of this waste, making it more productive and efficient. |

In a world where environmental stewardship is paramount, artificial intelligence (AI) is transforming the way we manage waste. Insects, and in particular the Tenebrio molitor, have proven to be the best nutrient converters, offering an efficient and environmentally friendly solution to the problem of industrial by-products. This blog explores how AI can revolutionise the management of these wastes, optimising their use as insect food and strengthening the circular economy model.

Industrial by-products represent a significant source of leftover materials generated during specific production processes related to the food and agricultural sector. These ‘wastes’, which include unused parts of raw materials such as fruits, vegetables or crops, often originate from activities such as food processing, fresh produce processing or ingredient manufacturing. In many cases these materials end up being discarded, which not only increases the volume of waste to be managed, but also implies the loss of valuable resources that could have a new purpose. In this context, the use of these by-products is of great importance, especially when they are used in the rearing of insects such as Tenebrio molitor. This approach not only reduces the waste generated by various industries, but also provides an extra nutritional contribution that complements the base feed and improves the growth and well-being of the insects.

The role of artificial intelligence (AI) in this proposal is fundamental, as it introduces advanced tools that optimise waste management and enhance its use. For example, AI can analyse and evaluate by-products from different industries using machine vision systems and machine learning algorithms. These systems facilitate the identification of materials with the greatest potential for use in insect feed, based on studies carried out in laboratories or specialised facilities. This approach optimises the screening process, allowing more efficient identification of waste that meets the necessary requirements. In addition, data-driven models are able to predict the nutritional value of the residues by analysing their protein, energy and other essential nutrient content, which facilitates the design of specific and optimal diets for insects. This is carried out using infrared or fluorescence spectroscopy, the chemical composition of the waste is identified, while machine learning algorithms process this information to assess the presence of contaminants, nutritional imbalances or unsuitable materials. This improves the efficiency of waste-to-protein conversion and reduces the risks associated with the process, ensuring the health and development of the insects.

The Tenebrio molitor presents itself as an ideal sustainable solution in this circular economy model. This insect has the ability to efficiently convert waste into high quality protein, with a process that generates significantly less environmental impact compared to traditional meat production, which requires large amounts of resources, such as land, water and feed, and generates high levels of greenhouse gas emissions. In addition to producing protein, Tenebrio molitor generates secondary by-products such as biofertilisers that can be used to improve agricultural productivity, thus closing the cycle of resource utilisation.

The combination of artificial intelligence and insecticides offers not only environmental but also economic benefits. On the one hand, the cost associated with industrial waste management is reduced, as it is used efficiently instead of being discarded. On the other hand, the ability to optimise nutrient conversion through diets specifically designed for insects increases the profitability of the system.

In a holistic approach, this model not only reduces greenhouse gas emissions by preventing large amounts of waste from ending up in landfills, but also transforms underutilised materials into valuable resources through insect farming. By minimising reliance on traditional protein production systems, which are highly resource-demanding and environmentally intensive, this solution promotes a more sustainable circular economy. This responsible approach represents an essential step towards a production system that meets the needs of protecting the planet.